Repairing the internal switch on

the Fiat Spider

You may click on the pictures

for larger versions

Additional Pictures

of the Ignition Switch: (Brad Artigue)

Expalnation of switch positions / wiring colors Here

Photo of rear of switch with color information Here

Pictures will open

in new window

| |

Tools and Parts List |

|

A

Fiat with a messed up ignition switch.

Soldering gun

1/8" drill bit

5/64" drill bit

Loctite |

Qty

4 2 x 20mm machine screws with nuts. (Were available at

my local Sears hardware). Other option is 5/64" x 3/4". |

Small

flat bladed screwdriver Tweezers

Needle nose pliers

Optional: Dremel tool with wire brush attachment. |

Procedure

I. Remove

the ignition switch. Believe it or not this will take you less than

5 minutes. The procedure is described nicely in the factory manual

but briefly ...

- Unplug both

connectors connecting the switch to the wiring harness

- Remove the

lower portion of the plastic steering column surround. If you

don't do it now, you'll have to later since the column lock will

catch on it as

you try to remove the switch from the housing.

- Insert key

into the ignition

- Turn key until

it aligns with the arrow stamped into the face of the switch.

This will allow the column lock to retract. It also sets things

up internally

within the switch so that you can push in the mechanism that

holds the switch

in the housing. See Figure 1.

- Remove the

boot at the back of the switch. Mine was already cut lengthwise

and held in place with wire ties so I just removed it. If it

is still intact you may

be able to simply slide it back.

- Remove the

2 set screws holding the switch to the housing.

- At about the

03:00 position on the switch/housing assembly there is a slot.

Take a small thin flat bladed screwdriver and push in through

the slot. While

pushing in with the screwdriver, push the switch from behind.

It should slide

out easily. If it does not, rotate the key ever so slightly in

one direction or the

other and try again. See Figure 1.

- The switch

may get 'stuck' after about an inch as you slide it out. Don't

panic,

it's probably the column lock catching on the metal of the steering

column.

You can remove the screwdriver from the slot now and use it to

gently pry the

column lock back the 1/8" that you need.

II. Remove

the electricals from the back of the switch.

- Lay the switch

on your workbench and take a look at it from behind. There

is a large internal circlip that is holding the electrical contact

assembly to the

back of the switch.

- Remove the

circlip nothing complicated about this.

- Remove the

contact assembly from the back of the switch by giving a gentle

tug on the pigtail. Set the main part of the switch aside. You're

done with that.

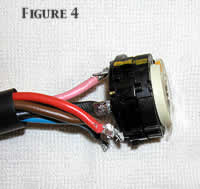

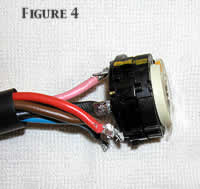

- Picture FIGURE

3 shows the circlip laying beside the switch assembly after

the contact assembly has been removed.

- Picture FIGURE

4 shows the contact assembly.

- Now, before

you go any further, take some sort of marker, paint, whatever

and

mark the 3 pieces that comprise the contact assembly relative

to each other.

That way when you put it back together all you have to do is

align the marks.

You'll see in picture FIGURE 4 that I used some yellow paint.

III. Un-solder

the connections

- First off,

MAKE A DIAGRAM OF WHERE ALL OF THE

WIRES ARE CONNECTED!

- Now it's time

to remove the 'pigtail' wiring from the spade terminals on the

back

of the contact assembly. This is a critical operation. A light-duty

hobbyist's

soldering 'iron' will not work very well. I suggest a Weller

or similar medium-

heavy duty soldering gun.

- The most critical

part of this operation is that you get as much of the solder

off

of the spade terminals as possible. Your success in this area

will pay off later as

you try to remove the spade terminals from the assembly.

IV. Disassemble

contact assembly Now the FUN BEGINS!

- Ever so carefully

take a drill with a 1/8" bit and begin drilling out the

crimped

part of the rivet at the center of the white plastic rotating

disk. Be very careful

not to go too deep. You're only trying to cut the crimp off with

the drill bit

tip so that you can press the rivet out later.

- Once the rivet

is cut, set the assembly so that it is resting on the spade terminals

and take a small screwdriver and carefully pry the disk off of

the main assembly.

In FIGURE 5 you can see the disk and its washer removed.

- Behind the

disk are 3 spring loaded pins. The ramps on the back side of

the

disc act on these pins to 'make' or 'break' the electrical contacts.

Carefully lift

these pins out with a pair of tweezers. Refer to FIGURE 11. Note:

This

picture was taken at the time of reassembly, that is why you

see screws

instead of rivets holding the assembly together.

- Now take your

drill bit and cut out the rivets holding the 2 black disks together

in the same way that you did in step 4.1

- Once the rivets

are removed, working around the perimeter, carefully pry the

2 black disks apart a little at a time.

- Once the disks

are separated you will see something similar to FIGURE 8.

Note that the top set of contacts in this picture are already

partially disassembled.

- Now, let's

see how good you were at removing all of the solder from the

spade terminals on the back of the assembly.

- From behind,

using your tool of choice, push a spade terminal back thru the

assembly. They are tight, but they WILL slide out. Be VERY careful

to maintain

the 90 degree bend of the contact assembly (opposite end from

the spade terminal.

- Now remove

the brass contact assembly and the 2 small springs underneath.

- Repeat this

process for all spade terminals.

When you're all done, you should have something that looks like

FIGURE 7.

- Now, break

out the Dremel tool and clean up all of the contact points with

a

wire brush attachment if you have one. Otherwise use some other

form of very

fine abrasive. Be VERY careful to only clean up the burned areas.

Remove as

little material as possible.

- Once everything

is cleaned up, remove the rivets from the assembly completely

(if you haven't done so already). You are going to replace them

with screws.

V. Reassemble

the contact assembly

- Using a 5/64"

drill bit enlarge the 3 holes around the perimeter of the 2 black

contact

assembly disks. You are doing this because the screws that you

are going to put

back in there are slightly larger than the original rivets. There

is NO NEED to enlarge

the center hole that secures the white plastic rotating disk;

it is large enough already.

- Now carefully

reassemble the contact assembly. This will require PATIENCE J

It is easiest to work on one contact set at a time.

- Drop the 2

little springs that the brass contact rides on into place.

- Lay the brass

contact on top with the contact points pointing up towards you

(away from the springs).

- Now, carefully

push the spade terminals for that contact back through the black

plastic

disk and push them all the way down until they make contact with

the brass piece.

FIGURE 8 shows the contact reassembly partially complete. Be

careful that the

springs under the brass contacts don't fall over.

- Once you have

all of the springs, contacts and spade terminals back in place,

use your alignment marks to put the 2 black disks back together.

- Before completing

the next steps please take note that nuts that you will use

will interfere with the internal circlip when you try to reinstall

the contact assembly

into the main switch. This is shown in FIGURE 12. My solution

was to cut the

circlip in a couple of pieces and use the nuts as 'stop' points

for the circlip. This is

not my preferred solution but it worked. If I had to do it again

I would grind one

side of the nut flat BEFORE I reassembled. I would grind it almost

to the point of

cutting into the threaded hole at the center of the nut. Then

the ring would be able

to slip past the nut and into its groove. If this works, shoot

me an email and I'll update

this document.

- Hold the 2

black disks together and insert a 2x20mm machine screw (or 5/64"

x 34")

and a nut (with Loctite) in each perimeter hole to hold everything

together. Make

sure to orient the screws as shown in FIGURE 10.

- Now trim the

excess thread from the rear of the assembly using a pair of wire

cutters.

- Next, put

the spring loaded pins back in place

- Next place

the white plastic rotating disk back into position and slip a

screw through it.

Orient the screw as shown Figure 12. On the spade terminal side

of the contact put a

drop of Loctite on the screw and install the nut.

- Solder the

wires back onto the contact assembly.

Place the contact assembly back into the ignition switch, taking

note that it will only fit

in 1 direction.

- Reinstall

the internal circlip

- Reinstall

the ignition switch in the car and YOU'RE done!

|

|